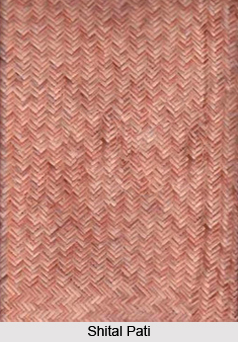

Sitalpati, literally means cool mats are very popular and aesthetic in design. These mats are luxurious in their feel and more expensive than other mats. Sitalpati mats are crafted from the marantra dichotoma or mutra reed. The finest sitalpati is used in Assam to sleep on, as it is cool for summer nights. The patikars (makers of mats) of Cachar and Dhubri districts of Assam make the sitalpati, an extremely fine floor. A relatively new design development has been the use of sitalpati mat cuttings as an embellishment on bags of all varieties, on pen stands and other table top items. It is used in plenty as a floor mat and a prayer mat and as a wall hanging.

Sitalpati, literally means cool mats are very popular and aesthetic in design. These mats are luxurious in their feel and more expensive than other mats. Sitalpati mats are crafted from the marantra dichotoma or mutra reed. The finest sitalpati is used in Assam to sleep on, as it is cool for summer nights. The patikars (makers of mats) of Cachar and Dhubri districts of Assam make the sitalpati, an extremely fine floor. A relatively new design development has been the use of sitalpati mat cuttings as an embellishment on bags of all varieties, on pen stands and other table top items. It is used in plenty as a floor mat and a prayer mat and as a wall hanging.

The production of sital pati is a household industry in Assam. Generally, men prepare the cane slips, while women do the weaving work. People mainly from Kacchhar district of Assam are involved in this craft. The mat makers mostly belong to the Muslim community. The villages famous for the production of sital pati in Cachhar district are Katakhal, Kaliganj,Basigram, Karimpur, and Sridurgapur.

Sitalpati Art

Sitalpati are lovely mats and very much expressive of its quality, made from green cane slips. The usual motifs are creepers, trees, animals, birds, geometrical designs and stylish human forms. Each design is enclosed in a square made up of lines. Sometimes different animals made in a single mat are also found. Circles are mostly repeated but with different decorations. Chowpat, a design of four squares with four empty squares are also made.

Procedure of making Sitalpati.

Procedure of making Sittalpatti

Procedure of making Sittalpatti

The manufacture of "sital pati" involves many complicated processes. Sitalpati is made from a marshy reed indigenous named as mohtra reed. Unlike reeds of the "khag" variety, it has no joints. Like other reeds, it grows on marshy and water logged areas and is found in abundance in choked up tanks and damp hill slopes.

The reeds are washed in soda and dried. Then they are split to clean out the soft stuff inside and sized to make all the pieces in equal width. These pieces are then boiled in water for three to four hours and dried. Colouring of the splits is done by indigenous methods. White (ivory) colour is obtained by boiling the splits in water, wherein other ingredients, such as boiled rice juice, hibicus safdariffa and tamarind leaves are mixed. For black colour, the splits packed into bundles are wrapped up with mango barks and kept under the mud for about 7 days. In order to obtain red colour, the cane splits are boiled in water mixed with "mezenta" (a kind of chemical dye-stuff).. After that, they are stiffened with starch (boiled rice water) and dyed if necessary. The splits are then woven in a closed weave and designs are made by using dyed slips. Generally the warp is of one colour and the weft of another. Some times two styles are worked together to produce a number of designs.

The sittal patti designs produced by the "patikars" of Assam are Fulpata (flower leaves with creepeers), Dalani, Cup-plate, Taj Mahal, Tree, Birds, etc.