Pottery involves making products out of clay. It is considered one of the oldest industries, with most ancient civilisations like Indus Valley, Maya, Inca, Egypt, China or Zimbabwe leaving its mark. Broken pots of clay were invariably found near almost all archaeological findings. In fact, world civilisation has grown with pottery and even in the contemporary era of synthetics, pottery is indispensable. The tradition of pottery as a craft in India is very rich, perhaps one of the richest. There is a tradition of blue pottery of Jaipur, black pottery of Azamgarh, the pottery of Khurza, Terracotta of Bengal and Odisha, clay models of different states and wonderful items like the "shitak" or village fridge of Vidarbha, and finally, the unsung pottery of Manipur.

Pottery involves making products out of clay. It is considered one of the oldest industries, with most ancient civilisations like Indus Valley, Maya, Inca, Egypt, China or Zimbabwe leaving its mark. Broken pots of clay were invariably found near almost all archaeological findings. In fact, world civilisation has grown with pottery and even in the contemporary era of synthetics, pottery is indispensable. The tradition of pottery as a craft in India is very rich, perhaps one of the richest. There is a tradition of blue pottery of Jaipur, black pottery of Azamgarh, the pottery of Khurza, Terracotta of Bengal and Odisha, clay models of different states and wonderful items like the "shitak" or village fridge of Vidarbha, and finally, the unsung pottery of Manipur.

The northeast Indian state of Manipur, geographically divided into the hills and the valley, has the hills with larger area but lesser population than the valley, inhabited by the tribes while the latter is home to people, bulk of whom are the Meitheis and the Lois, and to lesser extent the Bhishnupriyas, the Panggens (Muslims), the Mayangs (ones who migrated from other nearby states like the Assamese, Bengalis, Oriyas, Biharis etc.) and a few tribes. Manipur, irrespective of the demographic scenario, has grown as a state in its own right and even with encountering social changes, they adapted according to their own right. Like any other civilisation, Manipur grew with pottery. The tradition of pottery in the state varies considerably between the hills and the valley, the craft having grown independently in both the sides as per local need and market demand. The raw material input too differs between the two traditions and the clusters specialising in pottery have grown given the availability of clay in the vicinity.

Valley Pottery of Manipur

In the valley of Manipur, pottery is done only in few Loi villages. It is practised only by women and there is no habit of using potters" wheel. The pots are moulded with hand by beating. Four villages are well known for the art of pottery, namely Andro, Thamjao, Chairel and Shugnu. In Shugnu, the use of wheel has been reported. In Thamjao, wheel was introduced by the Manipur Khadi and Village Industries Board, who also got the artisans trained in making products like water filter. Andro continued with its old tradition. Scholar T. C. Hodson in his book "The Meitheis" reported that Chairel and Shugnu are the principal villages engaged in the pottery craft and business, probably because of the ready availability of suitable clay in their vicinity that is not seen elsewhere. He also stated that the use of wheel in these villages signify that their standard of skill has surpassed that of the Nagas, who mould their vessels on a bamboo cylinder and work it into a rounded shape by hand. The pots made at these Loi villages are brought by boat to the capital city Imphal and sold.

The pottery of the villages in the Manipur valley suffered a setback owing to various reasons, the foremost being the competition from cheap aluminium utensils which are also durable. These utensils that came from outside mesmerised the people of Manipur who swiftly switched over, making the artisans struggle for market. Their only products which found market were the ones meant for various rituals. Shugnu had a little edge over the other villages since the potters there adorned their pots with rough conventional patterns by stamping with wood, which could have been promoted as finer-finished fancy items and sold as terracotta tubs. Also to boost market, the artisans can switch over to garden pots or bonsai pots, which they craft to limited extent without any organised support. Products of modern taste can be made if glazing facilities are promoted and iron content in clay is kept minimal. As for Andro, which is famous for local distilled liquor called “Machingâ€, the pottery could thrive only because large pots were used for storing the liquor. The total marketability has diminished considerably since domestic demand for such pots has diminished as explained above. More consorted effort to develop products as per market need with training, design inputs and facilities like glazing etc. is necessary for survival of the art. Thamjao gets some support from Manipur Khadi and Village Industries Board, which itself suffers its own administrative and financial problems, affecting the village"s craft that could have survived if the same work would have been done by NGOs or cooperatives run by the artisan themselves. The Cooperative Act of the state needs to be reviewed for this purpose.

Tribal Pottery of Manipur

Most of the tribes of Manipur have no tradition of pottery. During yesteryears due to need, most of them would procure pots made by others. The quasi-Angami tribes like the Mao, the Marams and even a section of the Rongmeis used to procure the pots from Angami Naga potters village Khuzama. Therefore they never felt the need to promote pottery. It is reported that all the 3 Zeliangrong tribes - Rongmei, Zeme and Liangmei had some pottery traditions in their interiors but those clusters didn"t survive. Certain eastern Naga tribes used to procure their pots from Tangkhuls who had a couple of potters" villages. Most of the tribes close to the valley procured their pots from the Lois. The new Kukis till recently were nomads, even today migrating and the settled craft like pottery requiring different factors for its growth could not be developed by them. However, it is said that they had the tradition of pottery in their original abode inside Chin Hills of Myanmar. Kukis in Churachandrapur tried their hand initially but were soon discarded.

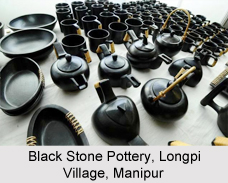

Thus, the most artistic pottery amongst the tribals has been noticed among the Tangkhuls found settled in the Ukhrul district. They have two potters" villages out of which Longpi is most famous. Pottery practised in Longpi is a traditional art followed on hereditary and wholly manual means, i.e., tribal coiled pottery. The basic material clay and stone rocks are available in a particular spot called Sahla in the village itself, at a distance of 8 kilometres from the Ukhrul district headquarters.

Pottery Items of Manipur

Village pottery articles of Manipur comprise cooking pot, earthen pressure cooker, earthen water filter, frying pan, table wares, decorative items etc. that are made by traditional coiled pottery by beating, casting, pressing and hand modelling methods in giving shape to the suitable designs out of clay and stone powder at the ratio of 3:2, which are further smoothed, dried and fired in traditional open fire and in fire furnace at around 900 degree C. The end products are either jet black pottery or brown and black mixed colour. The wares look artistic and possess efficient strength. The most wonderful item is the earthen pressure cooker, the design of which depends on the food to be cooked. Rice cooker has tapered centre for priming while for other dishes, the cooker is cylindrical. It has whistling system by providing a zigzag hole on the lid and the cross section is slightly oval so that by moving the lid pressure can be released. There is clamping system to clamp the lid while cooking. It has greater strength than ordinary clay pots to withstand pressure because the pot is moulded, with clay mixed with stone powder, by hand by beating thus having no pores like in ordinary clay pots. It may be noted that while rest of the world started using pressure cooker only a few decades back, the Tangkhuls used them since many centuries which reflects they had knowledge of pressure vessels traditionally much before the western scientists developed it.

Pottery in Manipur has developed virtually without many inputs and if proper plans are drawn and inputs given as needed, it can further grow into a wonderful craft.

Related Articles:

Manipur

Crafts of Manipur

Clay Crafts of India

Wood Craft

Stone Art, India

Pottery in Contemporary Age

Pottery in Harappan Civilisation

Tribes of Manipur

Pottery in Indian Villages