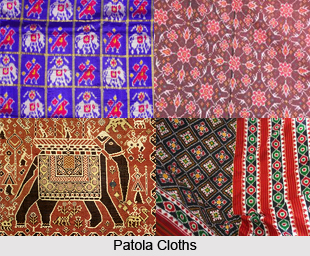

Patola is one of the finest dyed fabrics produced anywhere in the world and seen at its best in the silk wedding saris of Khathiwar and Gujarat. Patolas are one of the most beautiful products of the Indian handloom and among the most colourful of ancient Indian Textiles.

Patola is one of the finest dyed fabrics produced anywhere in the world and seen at its best in the silk wedding saris of Khathiwar and Gujarat. Patolas are one of the most beautiful products of the Indian handloom and among the most colourful of ancient Indian Textiles.

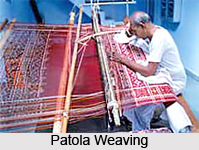

Fine Art Patola weaving

The famous Patola weaving of Patan is known for its colourful and strikingly beautiful patterns. It is characterised by tie and dye work.Some of the important designs are rattan chowk, in which diamonds cross with diamonds as they are interspersed around walnut, narikunja, dancing girl, parrot and elephant, chhabri is a basket made up by four elephants, waghkunjar, tiger-elephant. Also there is a variety of leaf and flower and geometrical patterns. The colours are vivid and pleasantly harmonised.

Procedure of making Patola Sarees

In making patolas, silk is always used as a yarn. The warp colours are dyed in the lightest colour to be used in the pattern, then the portions which are to be the next darker in shade are traced on a bundle of the threads either by charcoal or pencil. After completion of dyeing work of warps & wefts, the threads of the warp of different repeats of a pattern are put together in a sequence on the loom, so that the design becomes visible. The threads of wefts are wound on to bobbins and kept in the bamboo shuttle for weaving process.

The threads with in the pattern are then tightly tied with a cotton thread where the marks are made. The formula continued with threads that are to bear the next shades of the pattern until the darkest shades are reached. The weft is treated in the same way so that while weaving it crosses the warp, each of its colours synchronise with the same warp. In the weaving the weft is woven proper into the warp with extreme dexterity and precision. Thus the desired figures are obtained by juxtaposition of similarly dyed shades on equal lengths of warp and weft, and interlacing them.

The patola is woven on a primitive hand operated harness loom made out of rosewood and bamboo strips. The loom lies at a slant, with the left side being lower than the right side. The bamboo shuttle is made to move to and fro through warp shades. Each weft thread is thoroughly examined and matched with each part of the warp design pattern while weaving.