Metals have contributed during many ancient civilisations since Bronze Age and Iron Age. Archaeological evidences say that smelting of metals and formation of alloys had been practised since the ancient days, in civilisations like the Indus Valley. The land of Manipur was itself earlier known as "Subarna Bhu" and "Sna Laipak", both signifying Land of Gold. Thus, the northeast Indian state has had the flavour of metal in its name since the earliest times.

Metals have contributed during many ancient civilisations since Bronze Age and Iron Age. Archaeological evidences say that smelting of metals and formation of alloys had been practised since the ancient days, in civilisations like the Indus Valley. The land of Manipur was itself earlier known as "Subarna Bhu" and "Sna Laipak", both signifying Land of Gold. Thus, the northeast Indian state has had the flavour of metal in its name since the earliest times.

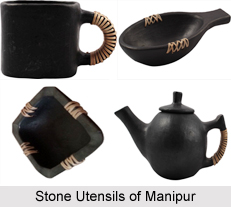

Manipur had its own typically distinct range of metal products. Both the forms of metal craft, the visible which can be seen in the end products and the invisible that names the process as the craft rather than the products, have been traditionally existent in Manipur. While the first survived up to a certain extent, the latter virtually languished despite the resources of the state.

Process Metal Craft of Manipur

Smelting of iron or copper from their respective ores or extraction of gold from ore belongs to the process category of metal craft. The visible craft obviously are the typical products made out of the process such as bell metal or brass items, items made of steel or other metals. The smelting of iron existed in Manipur even during the 19th century and early 20th century. Captain R. B. Pemberton in his "Report on the North East Frontier of India", which was drafted perhaps in 1835 AD, made the observation that Iron was the only metal ascertained till the time to exist in Manipur, found in the form of titaniferous oxydulated ore and obtained principally from the beds of small streams south of Thobal and the hills near Langatal where its presence was ascertained by the withered appearance of grass growing above it. In the former, iron was generally sought after the rainy season when the soil had been washed away. An iron headed spear was thrust into the ground and the small particles adhering to it lead to the accidental but striking discovery of the magnetic property being acquired by iron, which is preserved in the same position for any length of time. The spear of Manipuris and Nagas was almost invariably thrust vertically into the ground when not in use and the fact it was employed to ascertain the presence of the ore reflects the very high degree of magnetism or polarity it must have attained. The loss produced by smelting the ore amounted to nearly 50 per cent and the Manipuris were perfectly aware of the increasing difficulty of fusion with the greater purity of the metal. The principal articles made were such as would relate to the earliest stages of civilisation - axes, hoes and plough shares for felling timber and preparing the ground for agricultural purposes, spear and arrow heads for self-defence and blades from 1 to 2 feet in length, which when firmly fixed in a wooden or metal handle, formed the inseparable "dao" of the Manipuris, Burmese, Shan and Singpho people. It was used to clear the passage through the dense jungle and notch the steep and slippery hill.

Later T. C. Hodson made further study from where Pemberton left. Regarding the flux used in the process by those ancient smelters, Hodson reported in "The Meitheis" that limestone was probably used as a flux in the smelting process. During the period of Dr. R. Brown, an accident led to discovery of a shallow iron ore deposit at Kameng. Reports of Geological Survey of India in post independent era say that there a number of places limestone is available beneath the alluvial soil of the valley, while also confirming existence of iron ore. Therefore, even scientific reports confirm the observation made by the scholars. Col. W. McCulloch further specifies the report by Pemberton in his "Account of the valley of Manipore and of the Hill tribes", stating the Lois were exceedingly useful, being silk manufacturers, iron smelters, distillers of spirits, makers of earthen vessels for cooking or containing water, clusters of posts, beams and canoes, salt manufacturers, fishers, grass cutters for the Raja`s ponies, the payers of tribute in Sel, the coin of Manipur, etc. Thus, his report clarifies that the smelting art was actually mastered by the lowly placed Lois and not the Manipuris in general.

Iron, certainly not being a metal for fancy items, was all through used for producing utilitarian items, mostly agricultural implements. The ones used by the Meitheis include Kangpot (sledge), Langol (plough), Ukai Analba (smooth harrow), Phaointok (paddy spoon), Hummai (winnowing fan), Ukai Sampat (toothed harrow), Chairong (paddy thrasher or flail), Thanggol (sickle), Yot (spade), Thangchao (large dao) and Yeina Phak (thrashing mat). Not all these implements are made of iron, nor those in which iron is used are totally iron. In Yeina Phak and Hummai, iron is not used at all and in others, iron is used with wood in varied proportion like maximum in Langol and minimum in Thangchao. Most of them remain as agricultural implements till date, while the two types of Daos - Thanggol and Thangchao, for their peculiar shape and decorative handles are today used as decoration pieces, which is typical of the North East. The Meitheis used the spear, the dao and bows and arrows as weapons during yesteryears, which though discontinued since long, are still being manufactured either as decorative pieces or for agricultural or domestic operations.

Today, most of the insurgency groups in Manipur use sophisticated AK-47 or AK-56 rifles supplied to them by anti-Indian lobby from abroad. But not even most of the peace loving Meitheis know that Manipur had the tradition of manufacturing rifles, as recorded by Dr. R. Brown in 1874 - "The breech loader above mentioned, which is still in existence, is of iron and about three feet long; the breech piece is separable from gun and received the charge, its extremity being then inserted into the bore of the gun, a portion of barrel being cut out to admit of this; the movable breech piece fastened behind by a slot passing through the gun. The bullet weighed only a few ounces, the bore being small. The piece, carriage and all, was carried by two men. Nothing is known of the inventive genius who made this gun, except that he was a native of Munnipore; it is probably about a hundred years ago." However, various chronicles state the Manipuris learnt the process of manufacturing gun powder from the Chinese merchants who visited Manipur during the reign of King Khagemba. This reflects they had the knowledge of using guns several centuries back. The chronicles also reported that King Khagemba, in 1627 AD, experimented to make big guns and prepared one metal gun of big size. However, again as indicated by Col. McCulloch, the entire craft is credited to Loi population and not the whole of Meitheis.

The Nagas, new Kukis and old Kukis have never had any tradition of smelting of iron. They bought old pieces of iron to make their daos, spears and agricultural implements. Blacksmiths are still found in many villages but those who live close to the Loi hamlets buy them from the Lois, the workmanship being superior. Iron smelting in Manipur died long back and blacksmiths are struggling for survival against competition from mill made superior implements. Only daos and spears get made, being required for ceremonial reasons and often sold as fancy decorative goods. Ploughs are made but they will also taste the same medicine as tractors are rolling in. There is a need to think for revival of this process craft to regenerate the economy of Manipur. As of today, the state is gradually becoming a colony of India. There is also need for diversion of product line if iron smelting units are to survive.

Related Articles:

Manipur

Crafts of Manipur

Tribes of Manipur

Indian Metal Craft

Iron Age in India

Metal Art, India

Bell Metal

Nagas

Kukis

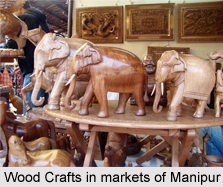

Wood Craft of Manipur