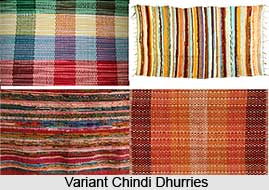

Chindi Dhurries are available in beautiful patterns. The patterns are of traditional and modern types. History of durrie weaving goes back to ancient times, when the concept of weaving had taken shape. This item of floor furnishing was manufactured in the villages and towns both for the household consumption and selling in the local market. Large floor and tent durries in solid colors and bold red/blue stripes and borders were made in cotton warp and unspun cotton owing to the varying sizes. The durries were woven on the horizontal devices, placed on the floor. The width of the device could be changed as per the size of durrie. Chindi durrie weaving is mainly practiced in Maharashtra and Uttar Pradesh. Today this industry is a major revenue earning resource. Chindi dhurries are most commonly used item in ones living room to bedrooms and very important use is seen in the prayer rooms.

Chindi Dhurries are available in beautiful patterns. The patterns are of traditional and modern types. History of durrie weaving goes back to ancient times, when the concept of weaving had taken shape. This item of floor furnishing was manufactured in the villages and towns both for the household consumption and selling in the local market. Large floor and tent durries in solid colors and bold red/blue stripes and borders were made in cotton warp and unspun cotton owing to the varying sizes. The durries were woven on the horizontal devices, placed on the floor. The width of the device could be changed as per the size of durrie. Chindi durrie weaving is mainly practiced in Maharashtra and Uttar Pradesh. Today this industry is a major revenue earning resource. Chindi dhurries are most commonly used item in ones living room to bedrooms and very important use is seen in the prayer rooms.

Fine Art of Chindi Dhurries

Fine Art of Chindi Dhurries

Over past few decades the Chindi durries have been impressively influenced by the designers intervention and a new range of concept in terms of sizes, colors, designs and forms opened the new vistas in the export market for the Chindi durries. The designs may be unicolour, multi-colour in cut shuttle technique. Craftsmen are more keen on working on geomatric designs as their favourite. The patterns are complimented with beautiful borders having all the possible colours. Block printing is also seen on the borders which is an ancient art.

Procedure of making Chindi Dhurries

The scrap cotton fabrics or leather are picked up in bulk and are shredded into small strips on the hasia generally by women. These strips act as the wefts during weaving. Dyeing may sometimes be carried out of the cotton warp chindis. The horizontal ground loom, consisting of two wooden beams, to which the warp threads are attached, is used for making Chindi durries. The designs are followed on the loom as per the graph. Chindis dyed in different colours are kept in different piles. Since the chindis have a restricted length, each Chindi is picked and inserted in the warp with fingers. If the same colour is repeated, another Chindi is inserted. At least two/three warps have double Chindi to avoid any holes in weaving. Panja is used repeatedly to set the chindis. Chindis are rotated round the warp bundle of three/four warps on the two corners at the beginning and at the end of each row. A little trimming is done here/there. These are then washed and finished.