Canes or rattans are slender stems found in certain trailing or climbing palms. In India, traditional bamboo and cane products have been prominent for a long time. The tribal communities have utilized bamboo and cane since ancient times, showcasing their creativity and artistic skills while also crafting practical everyday items. Various states in India, particularly those abundantly blessed with these natural resources, manufacture cane and bamboo handicrafts at affordable prices.

Canes or rattans are slender stems found in certain trailing or climbing palms. In India, traditional bamboo and cane products have been prominent for a long time. The tribal communities have utilized bamboo and cane since ancient times, showcasing their creativity and artistic skills while also crafting practical everyday items. Various states in India, particularly those abundantly blessed with these natural resources, manufacture cane and bamboo handicrafts at affordable prices.

The northeast region of India heavily relies on bamboo craft-making, which not only contributes to the local economy but also represents the rich cultural heritage of the area. These intricately designed bamboo crafts have gained global recognition and appreciation over the years. The furniture crafted from cane and bamboo exudes elegance and comfort, combining aesthetic beauty with practicality. The canes are native to principally the palm family of the genus Calamus in places like Assam, Arunachal Pradesh, Nagaland, Manipur and Mizoram, naturally-growing cane is abundantly available.

History of Cane Craft in India

The origins of this handicraft can be traced back to the 2nd century AD, as mentioned in classical literature that describes the vast bamboo and cane forests. Ptolemy documented the hilly and marshy regions of Assam where cane was used as bridges. In Hashacharitra, Bana provided evidence of the advanced craftsmanship in Assam during that time. It is recorded that King Bhaskara Varma of Assam sent intricately crafted goods to Emperor Harsha, which included baskets made from variously colored reeds, thick bamboo tubes, and birds housed in bamboo cages.

Types of Cane used for Craft

Commercially, three primary species of cane are commonly harvested, namely, Jati, Tita, and Lejai. Additionally, there are other lesser-utilized varieties such as Sundi and Raidang. Cane, known for its strength surpassing that of oak, exhibits remarkable resistance to water while providing an aesthetically pleasing appearance. This remarkable combination makes cane a sustainable natural resource and a pioneering material in the movement towards eco-friendly furniture.

Cane craft in different States of India

Although mainly concentrated in the north-eastern part of India, cane craft found significant popularity in eastern and southern part of the country as well. Each region is renowned for its unique artistry with cane that has been loved for its aesthetics as well as utility.

Cane craft in Assam: The state boasts an impressive array of 51 bamboo species, extensively utilized for various purposes, including construction, furniture, and ingenious inventions. Regardless of caste or community, numerous peasant groups in Assam actively engage in the art of cane craft. Through the dedicated efforts of skilled artisans and the region`s awe-inspiring natural resources, Assam has experienced notable socioeconomic growth and ongoing development. Farmers in Assam have the unique opportunity to partake in the household craft sector, primarily centered around bamboo and cane work.

Cane craft in Tripura: The art of bamboo and cane crafts showcases exquisite weaving patterns, distinctive aesthetics, and captivating designs in this state. Skilled artisans utilize basic tools to vertically split the bamboo and cane, achieving an impressive level of evenness on their surfaces. With these versatile materials, Tripuran artists skillfully craft a diverse array of stunning objects. This includes the Dulla or fish basket, Pathee or rain shield, Kula, dala, trays, pencil holders, lamp shades, and table mats.

Cane craft in Manipur: It is the second-largest producer of bamboo and bamboo products in the country, second only to Tripura. The state is renowned for its rich tradition of crafting bamboo and cane products. Certain districts in Manipur, such as Jiribam, Imphal, and Tamenglong, are particularly known for their abundant bamboo resources. The craftsmanship of Manipur shines through a wide array of objects made from bamboo and cane, serving both decorative and practical purposes.

Cane craft in Arunachal Pradesh: The bamboo craftsmanship in Arunachal Pradesh is characterized by its remarkable diversity, with designs, styles, and patterns that vary across different tribes. The state showcases an impressive array of popular bamboo and cane products, including Cane Belts, Baskets, Mats, Ornaments, Head Gear, Houses, Bridges, Smoking pipes, Trays, Knives, Barrels, and storage pouches.

Cane craft in Meghalya: The craftsmanship of Meghalaya encompasses a range of remarkable bamboo and cane products, such as Khoks, bamboo houses, mats, stools, and the unique Kurup— a special type of Khasi umbrella. These creations exemplify the mastery of Meghalayan artisans and their intimate connection with the versatile resources that surround them.

Cane craft in Mizoram: Mizoram possesses ample raw materials for bamboo crafts. Artisans in the region skillfully create a variety of bamboo baskets, serving multiple purposes. These baskets, available in different sizes and shapes, are used for storing vegetables, cotton, firewood, and grains. Additionally, Mizoram produces an array of cane products like pipes, toys, hats, umbrella handles, fish baskets, mugs, weaving tools, and even houses.

Cane craft in Nagaland: Bamboo crafting is an integral part of Naga culture, with expertise in creating exquisite furniture pieces such as tables, chairs, sofas, and cots using bamboo and cane. Cane baskets are also widely prevalent in Nagaland, and they are proudly flaunted by women as fashionable accessories.

Cane craft in Sikkim: With workshops dotting every lane where skilled artisans produce marvelous creations, cane craft thrives in Sikkim. The repertoire of Sikkimese artisans includes bamboo showpieces, mats, baskets, and furniture, among other exquisite products.

Cane craft in West Bengal: Countless skilled artisans in West Bengal dedicate themselves to crafting bamboo and cane mats of exceptional quality, as well as captivating and elegant screens and panels. Popular bamboo and cane items from the region include panels, screens, and mats, showcasing the artistry of West Bengal.

Cane craft in Kerala: This state boasts a vibrant tradition of crafting exquisitely painted mats and checkered black and white square boxes from bamboo and cane. These captivating creations not only make for excellent gifts but also invigorate the handicraft market of the region. Popular cane items from Kerala include Bamboo Boxes, Mats, and more, showcasing the artistry and allure of the state.

Cane craft in Uttar Pradesh: Allahabad, Kanpur, and Bareilly are renowned hubs for exquisite Cane and Bamboo work. These materials form the backbone of furniture and essential household items for daily life. The tradition of cane and bamboo work, passed down through generations, has flourished over the past 40 to 50 years. Artisans rely on their own imaginative ideas and skills to create intricate motif patterns, avoiding the use of traced designs.

Cane craft in Tamil Nadu: The districts of Chennai and Thanjavur are renowned for their exceptional cane products. The region offers a wide array of popular bamboo and cane items, including baskets, bowls, trays, furniture, and Kora Grass Mats.

Different methods of production is confined to the following types, e.g.

(1) Plaited or woven work,

(2) Wicker Work and

(3) Coiled basketry.

Plaited baskets

Plaited basketry consists essentially of 2 sets of elements i.e. warp and weft crossing each other. The baskets are prepared in different designs such as check, twilled, twined, wrapped and hexagonal. These Baskets mainly used for keeping clothes and ornaments, cane suitcases, etc. are generally prepared in this method.

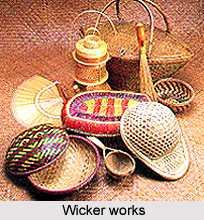

Wicker work

Wicker work

In a wicker work, the warp is not pliable, but the weft is pliable and passed alternately over and under the warp. In this method, the warp is kept in a lesser rigidity. Plucking baskets are prepared by following this method.

Coiled basketry

In Coiled basketry the warp is arranged by cane of comfortable length. Before arrangement, such cane is soaked in water for few minutes to give it a flexible character. Simply binding coiled cane while the process of weaving is in operation preserves the shape of the basket. Finally, the edge of the basket is stitched with a thin and flexible cane slip. Plucking baskets, ration baskets, baskets used for carrying earth, stone-chips, coal etc. are all manufactured in this method.

Procedure

Weaving, twining and coiling techniques are used for making cane baskets and mats. The production of reed and bamboo involves the cutting of whole stems with a hacksaw. It is then sliced longitudinally along the length of the densely packed fibres into splits of various sizes using a bill-hook or dao. A fairly smooth operation is done to retain moisture in the culm. Kerosene lamp is used to heat the cane before it can be bent into purely by hand. Occasionally the artisans use water to soften the splits.

Artefacts

Moshtha (multi-purpose floor covering), containers of various shapes and sizes tray. Floor covering mats, door mats, boxes, baskets, vases, bags, baskets, handbags, lampshades, furniture, container for drinking water, container for storing grain, lamps, lanterns, travel kit, sarki, chiks, curtains, dali, basket, pahi, tahuki, tapi, ganja, fish catching design, dhaki, big-size basket, pathia, small sizebasket, medhadambara, umbrella made of bamboo sticks

Lakshmi Casket

It is one of the oldest crafts of Bengal and Orissa. The famous Lakshmi casket is double walled, cane inside, and bamboo twill work outside. This is generally covered with a red cloth on which seven decorations like floral designs are worked out of small shells. There are oval boxes, oblong jhimpis and flower baskets called phulsajis. These are beautifully decorated with floral, figured and geometrical patterns using coloured strands as also accessories such as shells, beads etc.

The coil is fixed to another by sewing strips with two main varieties; the simple over coil where each stitch passes over the new portion of the foundation coil below, the other is where the figure of eight is worked. Here the stitch passes behind up, over and down under the preceding coil and right over the new coil. The fixing of the coil is done with bamboo splints. There is quite a wide variety in the coiled articles, ranging from rough storage jars to very elegant jewellery boxes.

Moorahs

Moorahs

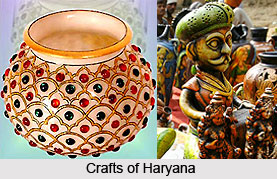

Chairs (Stools) called moorahs a major export item are made of bamboo and cane are manufactured in many parts of Haryana. With time and research the traditional moorah has undergone sea of changes in design and style. The seat is often artistically woven out of jute strings to make it more durable. A very large variety of items are made from raffia like baskets, trays, wall-decorations, children furniture being most attractive.

Cane or rattan is a kind of a climbing palm with long thin, solid and many joined stems. The stems are dried after removing the green sheath. It is extra ordinarily strong. After drying, the cane rods are cleaned and heated over a fire to make them pliable. Cane rods are used to make legs and supports and for actual interlacing cane splints are used. Low seats called mooras are made of bamboo and cane, the top being woven in artistic designs.

Rush Mats

Karai is a special kind grass growing wildly along the river banks. A peculiarity about this grass is that it can be used for the very fine varieties only when it grows wild. Every attempt to cultivate it has been frustrated because of the coarseness it develops when one tries to cultivate it.

Fine Art

This craft is a recent one and is located mostly in Shertallay and Mohamma in Alleppey district. Coarse grass is split open to remove the pith. To make a rush mat, generally 9 x 9, the pattern is first drawn out on the board with small nails followed by the grass splints guided through the nails or pins so as to fill in the pattern and each strand is bound to the other strands ensuring the pattern does not disintegrate. These rush mats, mostly square and round, ensure their dual usage in floor coverings as well as wall-panelling.

Procedure

The grass is first dried for 15 days in the sun until the green colour turns to golden then rounded into small bundles with stone tied to each to protect them from being washed away, then left immersed downstream shaded away from the glare, with all the attendant risks when bundle are left in flowing river. This soaked grass is then to be stored in a shed and waste is separated from the fine fibre split into thin wire-like strands for weaving. Twisted cotton yarn is used for the warp, after it has been rinsed in rice paste. The weaver sits on a low stool, to alternately press a split bamboo piece to do the necessary shedding. The warp threads actually pass beneath the sitting plank for as each weft is a separate strand it is not possible to use shuttle. The weft is therefore passed through the warp thread with the help of a long stick with a hole in it like a gigantic needle. Each grass strand, as it is to be pressed into the loom, is moistened with water. As the needle reaches the other end of the warp, the ends of grass are twisted and beaten into position by the reed, after which the shedding is provided and the weaver then starts again with a fresh strand to ensure closeness of the texture.