Iron and Steel Industry in India is a heavy industry. All its raw materials are heavy and massive. They encompass iron-ore, coking coal and limestone. Iron and Steel Industry necessitates enormous investment, proper infrastructure, able means of up-to-date transport and communication system and most importantly plentiful fuel or power supply. The major companies in this sector are Tata Steel, Steel Authority of India Limited (SAIL), Bhushan Power and Steel Ltd, Jindal Steel and Power Limited (JSPL) and Essar Steel. Fuelled by growing demands from automobiles, infrastructure, real estate sectors, the Iron and Steel Industry in India has gained global recognition.

Iron and Steel Industry in India is a heavy industry. All its raw materials are heavy and massive. They encompass iron-ore, coking coal and limestone. Iron and Steel Industry necessitates enormous investment, proper infrastructure, able means of up-to-date transport and communication system and most importantly plentiful fuel or power supply. The major companies in this sector are Tata Steel, Steel Authority of India Limited (SAIL), Bhushan Power and Steel Ltd, Jindal Steel and Power Limited (JSPL) and Essar Steel. Fuelled by growing demands from automobiles, infrastructure, real estate sectors, the Iron and Steel Industry in India has gained global recognition.

Development of Iron and Steel Industry in India

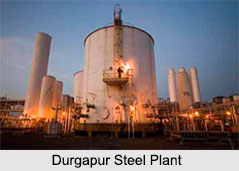

Iron and Steel Industry in India has experienced sustainable growth since independence. The beginning of the Steel Industry took place at Kulti in West Bengal in the year 1870. But the outset of bigger production became noticeable with the establishment of a steel plant in Jamshedpur in Bihar in 1907. The plant started production in 1912. This venture was followed by Burnpur Steel Plant and Bhadrawati Steel Plant in 1919 and 1923, respectively.

Structure of Iron and Steel Industry in India

Structure of Iron and Steel Industry in India

Iron and Steel Industry in India has 2 separate producers. They are the integrated producers and the secondary producers. Amongst the integrated producers, the major producers include Tata Iron and Steel Company Limited (TISCO), Rashtriya Ispat Nigam Limited (RINL) and Steel Authority of India Limited (SAIL). They generate steel by the conversion of iron ore. The secondary producers like Ispat Industries, Lloyds Steel and Essar Steel, create steel through the process of melting scrap iron. These are mainly small steel plants and produce steel in electric furnaces, using scrap and sponge iron. They produce both mild steel and alloy steel of given specifications.

Location of Iron and Steel Industry in India

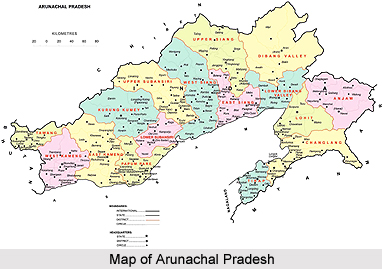

Location of Iron and Steel Industry in India is administered by its proximity to raw materials, predominantly coal. The finished products in turn are also heavy and need efficient transportation system for their distribution. The Chota Nagpur Plateau, bordering West Bengal, Bihar, Odisha and Madhya Pradesh is the natural nerve-centre of Iron and Steel Industry in India.

Significance of Iron and Steel Industry in India

Iron and Steel Industry in India is one of the most essential industries of the country which propels industrial development. It has helped in generation of several subsidiaries and small scale Indian industries and also supports power, transport, fuel and communication industries. It forgoes the heavy machines and tools industry. Umpteen light, medium, small and cottage industries depend on it, as a result of modernization and industrialization of India. Out of the 200 MT of total production of Iron and Steel Industry, about 50 percent is exported. Furthermore, iron ore exports have augmented by 17 percent because of its demand from China. Moreover, export duty levied on iron ore has been reduced. This provided impetus to the Iron and Steel Industry. Thus, augmentation in productivity in Iron and Steel Industry in India by adopting more effective and efficient technologies, will effect in amalgamating social, environmental and economic development objectives.