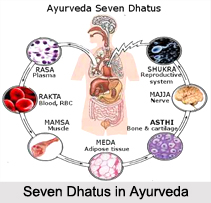

Mineral or inorganic medicines are generally described under 5 heads, namely, Rasa or mercury which forms a class by itself, Uparasa or metallic ores and earths, Dhatu or metals, Lavana or salts and Ratna or precious stones.

Mineral or inorganic medicines are generally described under 5 heads, namely, Rasa or mercury which forms a class by itself, Uparasa or metallic ores and earths, Dhatu or metals, Lavana or salts and Ratna or precious stones.

Metals and metallic compounds are subjected to a process of purification in order to get rid of their impurities or deleterious qualities. The metals, for the most part, are purified by repeatedly heating their plates and plunging them in the following fluids, namely, oil, whey, sour conjee, cow"s urine and the decoction of a pulse called kulattha. Another method of purification consists in soaking the plates of heated metals in the juice of the plantain tree.

Processing of Minerals

Metals and metallic compounds are reduced to powder by various processes. The operation is called marana, which literally means killing or destruction of metallic character but practically a reduction to powder, either in the metallic state, after conversion into an oxide or a sulphide. Various processes for the calcination of different metals are described in Sanskrit works on the subject.

Although the Hindus had made some successful efforts in preparing a certain number of chemical compounds such as chloride of mercury, sulphides of copper and silver, oxide of tin, some acids, alkalies, etc., yet their chemical operations were of a very rude and primitive character. The apparatus employed by them consisted of crucibles of different sorts, glass bottles and earthen pots arranged for sublimation of volatile compounds, retorts for distillation, sand and vapour baths, etc. The furnace for heating metals is usually a pit in the ground called Gajaputa. It is made one and a quarter cubits in depth, length and breadth. This is filled with dried balls of cow dung. The metals or metallic, compounds to be roasted are enclosed in a covered crucible and placed in the centre of the pit within the balls of cow dung, which are then set fire to and allowed to burn till consumed to ashes.

Different Yantras for Purifying Minerals

Mushayantra or crucibles are recommended to be made of husks of rice 2 parts, earth from ant-hills, iron rust, chalk and human hair cut into small bits, one part each. These are rubbed together into a paste with goat-milk, and made into crucibles which are dried in the sun. The compounds to be roasted are placed in one crucible, this is covered with a second, and the two are luted together with clay.

The sand-bath called Valuka yantra is made by filling an earthen pot with sand and heating it over the fire. Metallic preparations sublimed within glass bottles are heated in sand-baths.

When medicines, tied in a piece of cloth or other material, are suspended and boiled in a pot of water, the apparatus is called Dola yantra. The steam-bath called Svedana yantra is got up by covering the mouth of a pot of boiling water with a piece of cloth, placing the medicines to be heated by steam on this cloth, and then covering them with another pot.

For the sublimation of metals and metallic preparations, 2 sorts of apparatus are used. The first, called Urddhapatana yantra consists of 2 earthen pots placed one above the other with their rims luted together with clay. The lower pot containing the medicine is put on fire while the upper one is kept cool with wet rags. The sublimate is deposited in the interior of the upper pot. Sometimes the lower pot is covered with a concave dish and water poured into it"s hollow to keep it cool and changed as often as it gets hot. The second plan consists in placing the medicines to be sublimed in the bottom of a glass bottle which has been strengthened with layers of clay and cloth wrapped round it, and then exposing it to heat in a sand-bath. The sublimate is deposited in the neck of the bottle, whence it is extracted by breaking the latter.

Tiryakpatana yantra: This apparatus means the adjustment of retorts and receivers for sublimation and distillation.