Establishment of brocade weaving or silk weaving centres can be attributed to the efforts of the royal families and rich merchants of India. The rich merchants used to buy expensive raw materials that is silk and zari from the weavers. South India emerged as one of the major Indian centres of silk weaving, along with Gujarat and Malwa. In the north, Delhi, Lahore, Agra, Fatehpur Sikri, Varanasi, Azamgarh and Murshidabad were the main centers of brocade weaving. Mughal emperor Akbar also played a pivotal role in providing impetus to silk weaving in India by arranging royal textile workshops. Lahore, Agra and Fatehpur Sikri were the centres of these workshops. Here, skilled weavers from different backgrounds were brought together to work. Local weavers were blessed with the skills and knowledge of the expert weavers from distant lands. This led to a vast improvement in textile weaving in India

Establishment of brocade weaving or silk weaving centres can be attributed to the efforts of the royal families and rich merchants of India. The rich merchants used to buy expensive raw materials that is silk and zari from the weavers. South India emerged as one of the major Indian centres of silk weaving, along with Gujarat and Malwa. In the north, Delhi, Lahore, Agra, Fatehpur Sikri, Varanasi, Azamgarh and Murshidabad were the main centers of brocade weaving. Mughal emperor Akbar also played a pivotal role in providing impetus to silk weaving in India by arranging royal textile workshops. Lahore, Agra and Fatehpur Sikri were the centres of these workshops. Here, skilled weavers from different backgrounds were brought together to work. Local weavers were blessed with the skills and knowledge of the expert weavers from distant lands. This led to a vast improvement in textile weaving in India

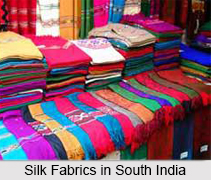

Silk Weaving in South India

Silk is known as "Pattu" in South India. Silk weaving originated in Hyderabad, Andhra Pradesh, Gobichettipalayam and Tamil Nadu. These were the first centres of automated silk reeling units. Although, southern states like Andhra Pradesh, Tamil Nadu and Karnataka contribute vastly to the total mulberry raw silk production in India, the silk produced here is merely two-thirds of the demand. The most popular varieties still continue to be the native Mysore races and Kanchipuram silk. Here, handloom and powerloom silk weaving are both prevalent, but it is the hand woven silk materials, which are in high demand by national and international buyers. Southern silk sarees allure even foreigners, who cannot leave India without buying them.

Leading Silk Regions in South India

Andhra Pradesh is renowned for its hand-woven silk fabrics. It produces the most exclusive silk sarees and dress-materials. The silk weaving techniques used here are handloom silk weaving and ikat technique. Exclusive to Andhra Pradesh, Ikat technique of weaving is extremely popular throughout India. Dharmavaram, Pochampalli, Venkatagiri and Narainpet are the major silk centres in Andhra Pradesh.

Tamil Nadu is well known for its hand-woven "Kanchipuram" silk sarees. Embroidered with zari intensely, these sarees are large and heavy. These sarees are well known throughout the world for its well-defined weaving patterns and good quality silk. Arni, Salem, Kumbhakonam, Tanjavur are the major silk centres in Tamil Nadu.

Karnataka is recognized for its Mysore silk sarees. The Mysore silk industry is more than a hundred years old industry. It enjoyed monopoly in the world of silk fabrics for several years, before global recession adversely affected its smooth run. The zari borders are a characteristic of the Mysore silk sarees and give them their special identity. Bangalore, Anekal, Ilkal, Molakalmuru, Melkote, Kollegal are the prominent silk centres in Tamil Nadu.

Type of Silk Weaving in South India

With time silk weaving in India has undergone various stages of evolution that resulted in different patterns and techniques of silk weaving giving rise of various silk fabrics.

Brocade Weaving: Silk is the essential pre-requisite of brocade weaving. Type of silk used in this kind of weaving are Tanduri, Banaka and Mukta. The various kinds of brocades are pure silk, silk and cotton blends and zari brocades with gold and silver threads.

Tricks of Tie and Die: It involves two techniques. The patola or ikat technique involves the dyeing of the tie-resist yarn. The bandhej or bandhini involves the dyeing of the fabric. In Odisha ikat is done using yarn resist method for both warp and weft with diffused effect. The beautiful design emerges with confident strikes of a brush. Both mulberry and tasar silks are the chief ingredients in Ikat weaving.

Handloom Silk Weaving: It is the manual operating system, thus leading to comparatively lesser production and having slow running sreed. Here initial investment is low and less variety is produced.

Powerloom Silk Weaving: It is the electrical operating system, thus leading to relatively higher production and having high running speed. Here initial investment is high but high variety is produced. Given the advantages of powerlooom silk weaving, it would be surprising to know that, handloom silks edges over powerloom silks in terms of beauty, texture, design and uniqueness.

Silk Sarees and Other Silk Products

Indian women identify themselves with sarees. Silk sarees define traditional Indian women. Silk sarees are in fact part of India"s cultural heritage. Indian weavers have astonished the world with their choice of fabric, artistic knowledge, incredible and inexhaustible designs, and outstandingly neat prints. This is evident in huge demand for silk sarees throughout India. Embroidery or crystal decorations of these sarees are made to the silk, or even in cotton and silk-polyster versions for the lower end of the market. The pallu of these sarees woven in South India carry designs of temple towers, palanquins, elephants, birds and creeping lotuses. Now, the export of these silk sarees woven in South India is increasing every year by earning some crores of rupees as foreign exchange. Other silk products include dress materials, scarves/stoles, readymade garments to name a few.

Indian government has taken a step towards the growth of silk industries in India. It has set up the Central Silk Board which is a statutory body, under the administrative control of the Ministry of Textiles, Government of India. Established in 1948, by an Act of Parliament, the CSB has been entrusted with the overall responsibility of developing silk industry covering the full gamut of sericulture activities in the country from development of food plants to silk cocoons for production of silk yarn including formation of policies governing import & export of silk.