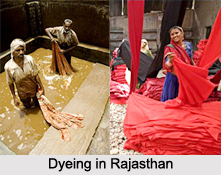

Dyeing in Rajasthan has a special significance for its tie and dye clothing. However, the process of dyeing is famous all over India. Dyeing is the process used in Rajasthan for imparting colours to a textile material in loose fibre, yarn, cloth or garment form by treatment with a dye.

Dyeing in Rajasthan has a special significance for its tie and dye clothing. However, the process of dyeing is famous all over India. Dyeing is the process used in Rajasthan for imparting colours to a textile material in loose fibre, yarn, cloth or garment form by treatment with a dye.

History of Dyeing in Rajasthan

For almost 1000 of years, dyeing has been used by humans to decorate clothing, or fabrics for other uses, the primary source of dye has been nature, where the dyes being extracted from animals or plants. In the last 150 years, man has produced artificial dyes to achieve a broader range of colours and to render the dyes more stable to resist washing and general use.

Process of Dyeing in Rajasthan

Different classes of dye are used in Rajasthan for different types of fibre and at different stages of the textile production process from loose fibres through yarn and cloth to completed garments.

Rajasthan also has a wealth of dye-yielding plants and the waters of its rivers seem to have special properties that derive the vivacity of the colours in which the materials are dyed. Each region in Rajasthan has its distinctive hues, which are rich and unique because of the quality of water and processes used. Traditionally, dyeing and printing centres were usually located near a river or some other source of water. The final outcome in shades of colour depends on various factors, like exposure to the sun, hardness of water and whether it was still or running water. The fabric that is used for dyeing is "Greige" cloth or the unprocessed material, straight from the loom and in the traditional dyeing practice, is usually first treated with a "Telkhar" emulsion. This emulsion is prepared with oil, khar or river residue and sheep or goat dung. It is applied to de-size, bleach and make the fabric soft and absorbent for further treatments.

Harda powder or myrobalan tannin, a chemical agent that also acts as a mordant, is mixed with water to prepare the Pila Karna solution. This is used to treat cotton fabric, which has an inherently low affinity for natural dyes. The harda treatment improves the cloth`s affinity to the dye and improves dye-fastness. The fabric is soaked in pits containing this solution and beaten for even penetration. This imparts a pale yellow colour to the fabric. Although chemical dyes are usually used in large-scale textile production, many artisans still retain the traditional methods and materials.

Colours for Dyeing in Rajasthan

Natural materials are commonly used for dyeing include alizarin, myrobalan, iron tilings, jaggery, turmeric, alum, kesula flowers, indigo and pomegranate rind. Of these, the most popular are alizarin, indigo and pomegranate rind.

•Red: Alizarin is a red dye, most extensively seen on textiles. One of its natural sources is the root of the madder plant. The alizarin extracted from this root mixes with alum to produce a rich red colour. Both natural and synthetic alizarin is used on fabric, which is dyed in a copper vessel. The required amount of alizarin is dissolved in water to obtain the desired shade of red. The fabric is then immersed in a heated dye bath. As the temperature is raised, a red colour develops in the areas printed with begar paste (alum mixed in gum, which acts as the mordant). Eventually, the fabric is washed and dried before the next treatment.

•Blue: Neel or Indigo, the blue dye, is also frequently used in Rajasthan and surrounding region. It is extracted from the leaves of the indigo bush, although synthetic indigo is now readily available in the market. As both natural and synthetic indigo are insoluble in water, the dye is first made soluble by reducing it during the treatment with an alkaline solution. The fabric to be dyed is then dipped in the cold solution and on exposure to air oxidizes to a blue colour. Extended and repeated treatment in the dye bath produces a fast, dark blue.

•Yellow: A rich yellow hue comes from the dye known as Nashphal. This is obtained by boiling dry green rinds of the pomegranate fruit. Another yellow dye is the pomegranate solution that is produced by boiling pomegranate rind, turmeric and oil in water. The technique of application is known as "Potna" which literally means `to smear`. The solution colours the fabric to a rich yellow.

•Black: The colour, black, comes from a dye produced by fermenting scraps of iron with jaggery. This, when thickened with a gum solution, attains a suitable viscosity for printing and the paste that is called "Syahi".

Each of these dyes combined with the various different dyeing and printing techniques creates the variety of designs and colours that are admired in the everyday life of the people of Rajasthan. Rajasthan has a number of dyeing centres. The most prominent dyeing centres in Rajasthan are at Jodhpur, Jaipur and Sikar. Sikar produces some of the finest dyeing fabrics and they produce a range of patterns, which are made for different communities in Rajasthan, Haryana and even Punjab.