Aluminium is one of the most significant metals produced in India. In the country, it holds a position next to iron. Since the year 1960, production of aluminium in India has been tremendously rapid. Aluminium is also considered as an important non-ferrous metal. Further, this significant Indian mineral resource has wide applications, thus, it is of strategic and economic importance. Unlike aluminium, production of copper, zinc and lead falls short of domestic requirements. Because of the considerable increase in the manufacture of aluminium, India exports it and alumina worth huge amount of money every year.

Aluminium is one of the most significant metals produced in India. In the country, it holds a position next to iron. Since the year 1960, production of aluminium in India has been tremendously rapid. Aluminium is also considered as an important non-ferrous metal. Further, this significant Indian mineral resource has wide applications, thus, it is of strategic and economic importance. Unlike aluminium, production of copper, zinc and lead falls short of domestic requirements. Because of the considerable increase in the manufacture of aluminium, India exports it and alumina worth huge amount of money every year.

Interestingly, around half of aluminium produced in the country is utilized by electrical industries. Aluminium is specifically used in the production of reinforced aluminium conductors and sheathed cables. This mineral resource is recovered from alumina by electro-chemical processes. That is why, aluminium smelters are situated near the sources of electricity. Almost one-fourth of the creation cost of aluminium metal is accounted for by electricity. In India, smelters producing aluminium metal are situated at several places like Jaynagar near Asansol, Hirakud Dam, Mettur Dam (Tamil Nadu), Alupuram (Kerala), Belgaum (Karnataka) and Renukoot (near Rihand Dam).

Moreover, Government of India has set up an integrated aluminium project at Korba (Chattisgarh). This aluminium project is based on the bauxite deposits situated in the Amarkantak Plateau and Phutka Pahar located around 15 kms to the north of Korba. This aluminium plant began producing alumina in the year 1973 and aluminium in the year 1975. The annual capacity of this project is very huge. Extrusions are made from the aluminium supplied by the Korba aluminium plant at smelters situated at J.K. Nagar. Moreover, in India, aluminium fluoride and cryolite used in the production of aluminium metal are manufactured in India.

Moreover, Government of India has set up an integrated aluminium project at Korba (Chattisgarh). This aluminium project is based on the bauxite deposits situated in the Amarkantak Plateau and Phutka Pahar located around 15 kms to the north of Korba. This aluminium plant began producing alumina in the year 1973 and aluminium in the year 1975. The annual capacity of this project is very huge. Extrusions are made from the aluminium supplied by the Korba aluminium plant at smelters situated at J.K. Nagar. Moreover, in India, aluminium fluoride and cryolite used in the production of aluminium metal are manufactured in India.

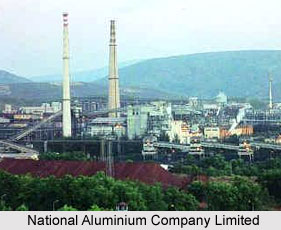

Largest aluminium complex in India is the National Aluminium Company Ltd. (NALCO), in Orissa. However, the alumina plant and the smelter of this complex are at different places. The production cost of aluminium in India is moderately high mainly because of high rate of electricity, inadequate supply of electricity and some raw materials like cryolite, aluminium fluoride, caustic soda, etc. and lastly regular interruptions in the supply of bauxite. These are some of the reasons that hinder the production of aluminium In India.