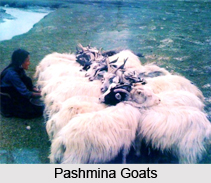

Pashmina is a kind of cashmere wool. Its name is derived from an ancient Persian word Pashm, meaning "made from wool". It is also known as the Diamond Fabric or Soft Gold. Four distinct breeds of Cashmere goat form the source of this type of wool. They are the Changthangi or Kashmir Pashmina goat from the Changthang plateau in Kashmir region, the Malra from Kargil area in Kashmir region, the Chegu from Himachal Pradesh in northern India and Chyangara or Nepalese Pashmina goat from Nepal. Pashmina undoubtedly is a vital part of Indian textile, with Kashmir being the first place to manufacture textile using pashmina wool. Reduction of goat herds in Ladakh due to blizzards and the ongoing war in Kashmir has resulted in China gaining prominence in the field of pashmina production, from a past couple of decades.

Pashmina is a kind of cashmere wool. Its name is derived from an ancient Persian word Pashm, meaning "made from wool". It is also known as the Diamond Fabric or Soft Gold. Four distinct breeds of Cashmere goat form the source of this type of wool. They are the Changthangi or Kashmir Pashmina goat from the Changthang plateau in Kashmir region, the Malra from Kargil area in Kashmir region, the Chegu from Himachal Pradesh in northern India and Chyangara or Nepalese Pashmina goat from Nepal. Pashmina undoubtedly is a vital part of Indian textile, with Kashmir being the first place to manufacture textile using pashmina wool. Reduction of goat herds in Ladakh due to blizzards and the ongoing war in Kashmir has resulted in China gaining prominence in the field of pashmina production, from a past couple of decades.

History of Pashmina Wool

The 15th century ruler of Kashmir, Zayn-ul-Abidin, is credited with the establishment of Pashmina industry in India. Some sources give the credit to Mir Sayyid Ali Hamadani, for the introduction of pashmina crafts. In 2014, the United Nations specialized agency called UNESCO (United Nations Educational, Scientific and Cultural Organization) reported Ali Hamadani to be one of the major historical figures influencing the culture of Kashmir. He had a major role to play in the economy of Kashmir via architecture and the flourishing arts and crafts. In 14th century, he came to Kashmir along with 700 craftsmen from different parts of Persia. He therefore came to Kashmir with skills and knowledge which blossomed into an entire industry. On his visit to Ladakh, home land of pashmina goats, he discovered that the Ladakhi goats produced soft wool. He took some wool and made socks and gave them as a gift to king of Kashmir, Sultan Kutabdin. He also suggested the king to start a shawl weaving industry in Kashmir, using this particular wool. It is also important to note that Afghan texts mentions woolen shawls being made in Kashmir between the 3rd century BC and the 11th century AD.

Features of Pashmina Wool

A very unique characteristic of pashmina is that it becomes softer and more comfortable with each use. If handled with care, this fabric will last a lifetime or more. The quality of pashmina is perceptible from the fact that pashmina has been transferred from one generation to another in royal and wealthy families, throughout the world. Pure pashmina is delicate and cannot tolerate high tension. Good quality pashmina can also be judged from its warmth and feel. One difference between pashmina and generic cashmere is the fibre diameter. Pashmina fibres are finer and thinner about 11-15 microns than generic cashmere fibre which is about 15-19 microns.

Processing of Pashmina Wool

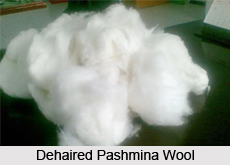

Processing of pashmina is an old age tradition in Jammu and Kashmir. Pashmina products are not only known in the world for their quality, but also for the way they are prepared. The various steps involved in the preparation of pashmina are dusting, dehairing, combing, spinning, dyeing, weaving and knitting and finishing.

Adventitious particles like dust are contained in the fleece of pashmina goats and are removed by a process called dusting, either manually or passing through dusting machines. Then the guard hairs are removed. This is done meticulously with minimal loss of valuable fibres. This process is called dehairing, which is either done manually or with machine. Wooden combs are used to comb pashmina. Combed pashmina turns into a loaf called Tumb. It is then glued usually with soaked powdered rice. Combing is done manually. The tumb is then spinned on the traditional charkha or spinning wheel to make yarn, which is collected on small bobbins. Next step is to use the hand reeler to double the spun yarn. The spun yarn is then ready for dyeing with only natural ingredients, mostly organic compounds. Dyeing helps in producing different colours, depending on the concentration used. The yarn is then weaved on local handlooms into various designs like the Jamawer and kanizama. Dyeing and embroidering is done for value addition, washing and pressing in a process called finishing.

Production of Pashmina Wool

The pashmina goat called Changthangi in Kashmir naturally sheds its winter coat every spring, which regrows in winter. This under fleece is collected by combing the goat. The pashmina goat feeds on the grass as well as the roots of the grass. Approximately 4 to 8 ounces of pashmina fibre is shed by each goat. Fibre from two to three goats is combined to manufacture one good quality pashmina product like a shawl or stole. It is also important to note that the pashmina fibre which is closer to the body of the goat is of better quality than the one on the outer side.

The production of pashmina depends on a number of factors. One of the major factors is the number of hair follicles per unit body surface. Fibre production is also influenced by lactation. Pashmina production is more in males than females due to the difference in body size. Pashmina production is also different in different body regions in case of both male and female goats. The length of the fibre obtained from different body regions therefore varies. Production is also affected by sub zero winter temperature, as pashmina grows as an undercoat and functions to protect the pashmina goats.

The production of pashmina depends on a number of factors. One of the major factors is the number of hair follicles per unit body surface. Fibre production is also influenced by lactation. Pashmina production is more in males than females due to the difference in body size. Pashmina production is also different in different body regions in case of both male and female goats. The length of the fibre obtained from different body regions therefore varies. Production is also affected by sub zero winter temperature, as pashmina grows as an undercoat and functions to protect the pashmina goats.

A tribe called the Changpa is credited with the label of being the traditional producers of pashmina wool. They are found in the Changthang plateau of the Kashmir region. Temperature condition of this region is suitable for rearing of pashmina goats. This place has a lowest altitude of about 13,500 feet above the sea level and the winter temperature drops to 40 degree Celsius. These people are nomadic and rear sheep in this harsh climate for meat and pashmina goats for wool. The raw wool is then transported to the valley of Kashmir, where it is entirely hand processed by specialized craftsmen and women.

Although India contributes only about 1% to the world"s pashmina, but the pashmina produced in India is renowned throughout the world and is considered the best. The main centre of pashmina fabric production is Srinagar, capital of Kashmir. Other centres of pashmina production in India are Ladakh region of Jammu and Kashmir, Lahul and Spitti valley of Himachal Pradesh, Uttar Kashi, Chamoli and Pithargarh districts of Uttranchal. The pashmina obtained from Jammu and Kashmir is known as Changthangi Pashmina whereas that obtained from Himachal Pradesh and Uttranchal is known as Chegu Pashmina.

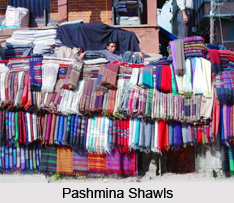

Pashmina Products

The Pashmina fibre is very less in diameter. Therefore, it is hand-processed and woven into warm wears like scarves, wraps, throws, shawls and in rare cases, macho. The quality of a finished product is not solely dependent on the diameter of the wool but also on the expertise of the craftsmen. Pashmina shawl being expensive is not subjected to amazement because of the expertise involved in making these shawls along with the fact that the Changthangi breed of the Capra Hircus goat constitutes less than 0.1% of global cashmere production. It has been estimated that the approximate craft time required to produce a single pashmina stole (70x200cm) is 180 hours. The most popular pashmina fabric is a 70% pashmina with 30% silk blend. Characteristically, this kind of pashmina is tightly woven but is still soft and light-weighted. It has remarkable sheen and also drapes nicely.

Related Article:

Indian Clothing

Pashmina Shawls

History of Pashmina wool

Silk, Indian Fibre

Woollen Textiles in India

Materials for Indian Clothing